MARKETS

Pipe Fabrication

Streamlining pipe trades work through innovative prefabrication methods

Fabrication of pipe trades materials is a vital part of the construction process. The amount of time that is saved by pre-fabricating materials is vital to cost-saving.

Fabrication goes beyond prefabrication of materials and sending them off to job sites. The fabrication process includes detailed engineering of how materials should be welded and threaded, designing of materials, knowing where stress points are, what is the best process for assembling materials and more.

Southwest Pipe Trades Association and United Association affiliated unions train members in fabrication

By applying for and completing a registered apprenticeship program with one of our affiliated UA Local Unions, you will have a working knowledge of fabrication in the pipe trades industry.

There are two types of fabrication in the pipe trades industry, pipe spool fabrication and modular fabrication. SWPTA affiliated unions can provide you all of the knowledge and job site experience needed to become an expert in both of these fabrication processes.

SWPTA and United Association members promote the southwest oil and gas industry through pipe spool fabrication.

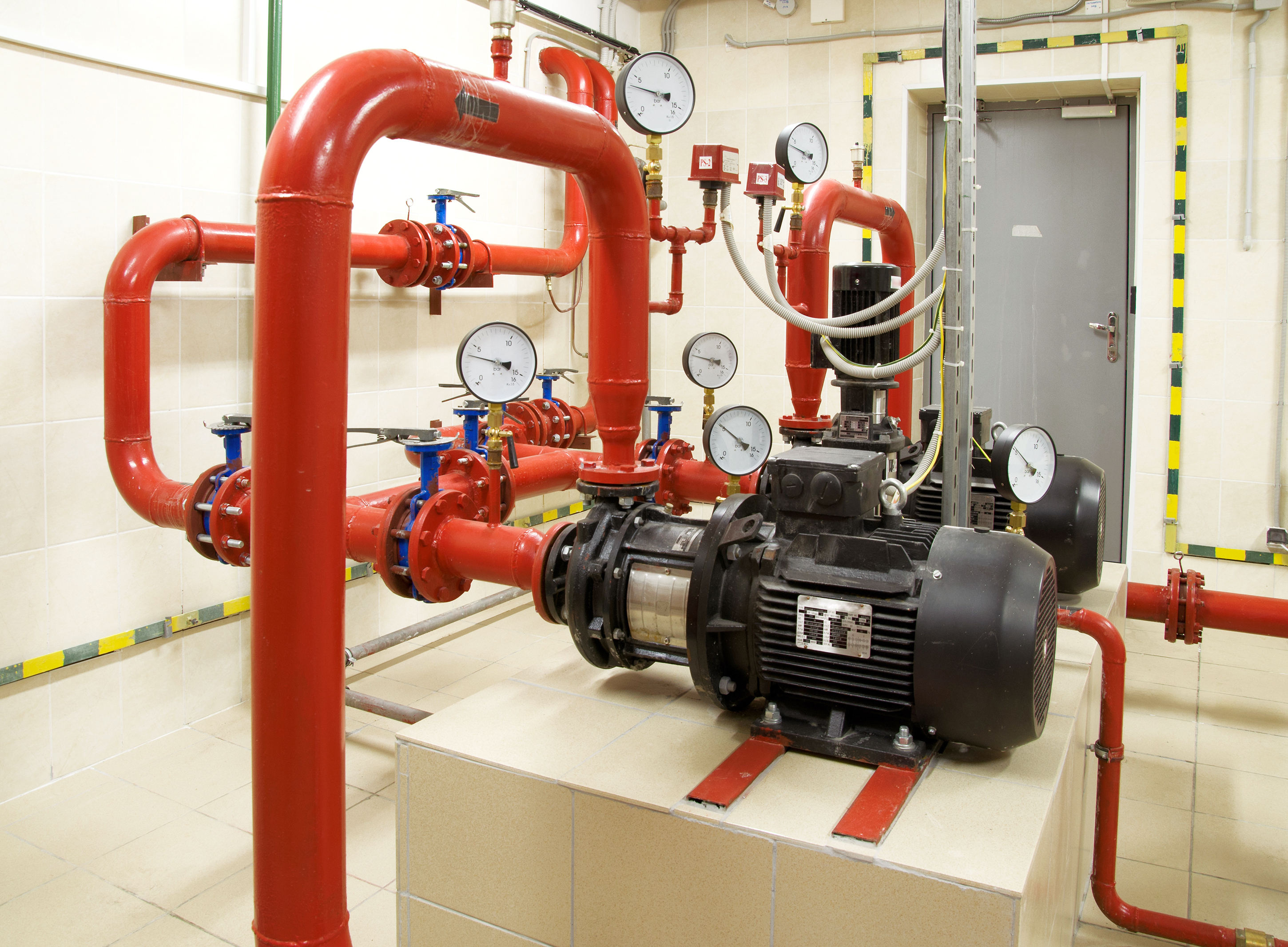

Pipe spool fabrication is the cutting, beveling and welding of pipes. It is frequently used in the oil and gas industry, where a large volume of heavy pipe is required. The process consists of cutting pipe, fitting the pipe and then welding it together in a shop to be sent to job sites in its pre-assembled form.

Pipe spool fabrication is heavily used in the oil and gas industry, power plants, refineries and other large industrial facilities.

SWPTA and United Association union pipe tradesmen and tradeswomen use modular fabrication to improve speed, making projects more efficient

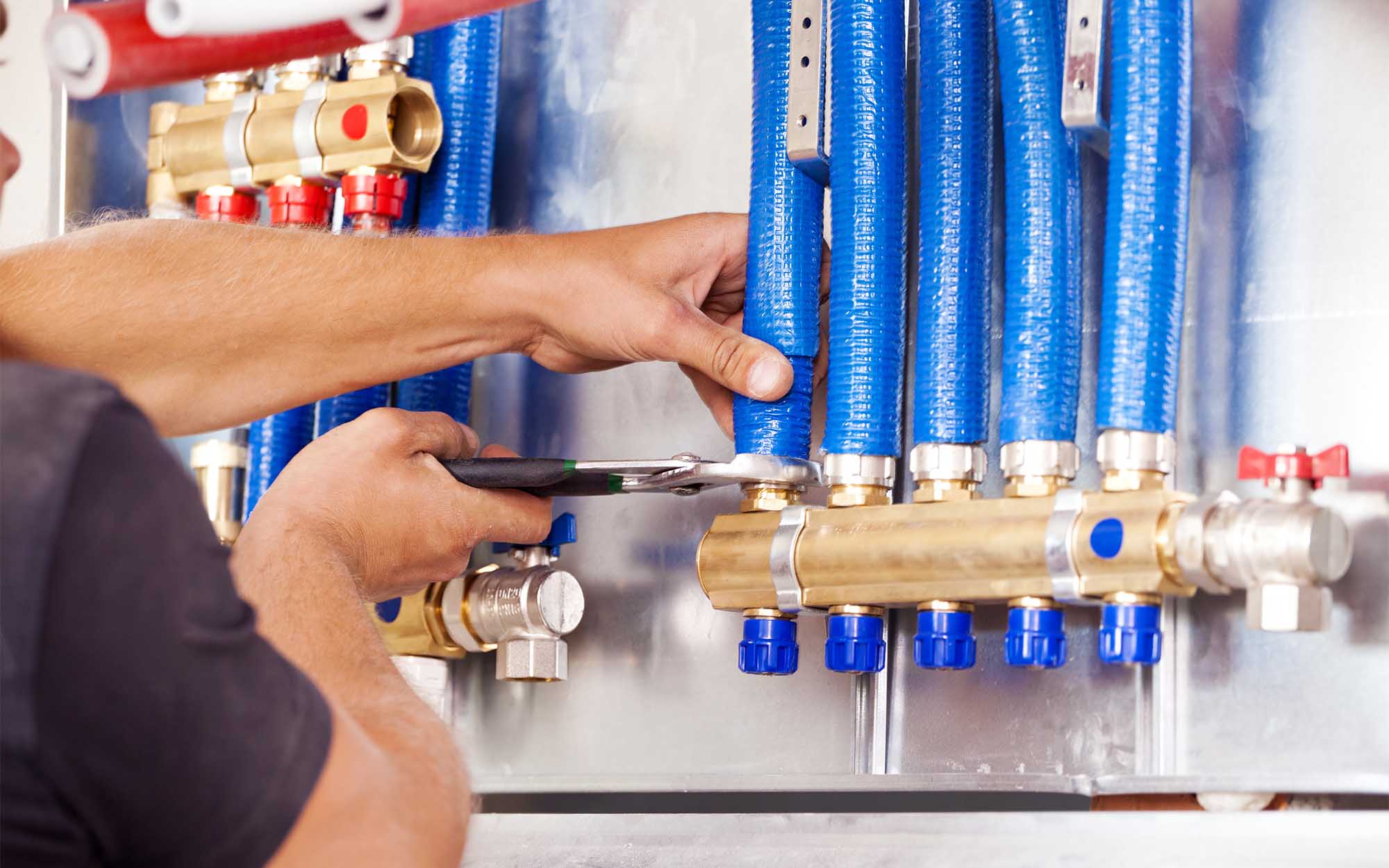

Modular fabrication in the pipe trades refers to the fabrication of job site materials in a shop setting using modern technology to deliver a consistent product with a high level of quality. By making these materials in a controlled shop setting, the quality control is much better and there are less human errors made on job sites.